Custom steel processing

At RPG Australia, we have built an enviable reputation in custom steel processing techniques using advanced machining and software technologies. We offer the complete suite of heavy steel processing capabilities backed by our technical skills and unmatched expertise. All our steel processing services, including plate rolling, plate bevelling, plate profiling, brake pressing, section curving and CNC machining is all under one roof.

With guaranteed material supply and Australia-wide delivery, we maintain our status as Queensland’s first choice for custom steel and machining.

Plate profiling

Leaders in plate steel profiling and bevelling, we use the latest forming equipment with 45-90° rotation with plasma cutting and drilling capability up to 80mm thickness for carbon steel and 50mm thickness for stainless steel.

Brake pressing

Our six brake pressing machines can press all manner of materials, with a pressing capacity range from 300 – 2700 tonne.

BIS 80, 400, 450 and 500; Xlerplate 250 and 350 grade; Strenx 700, Hardox 450 and 500, and also all grades of aluminium and stainless steel as well as other exotic grades.

Plate rolling

With five plate rolling machines, our technical skills enable us to create a myriad of shape styles, including conical sections, cylinder, strakes, elliptical sections, multi radii and spirals.

Section curving

Ideal for specialist projects, our seven steel section curving machines can bend and roll a variety of materials, with the capacity to roll multi radii, cold-formed sections, stainless steel and aluminium.

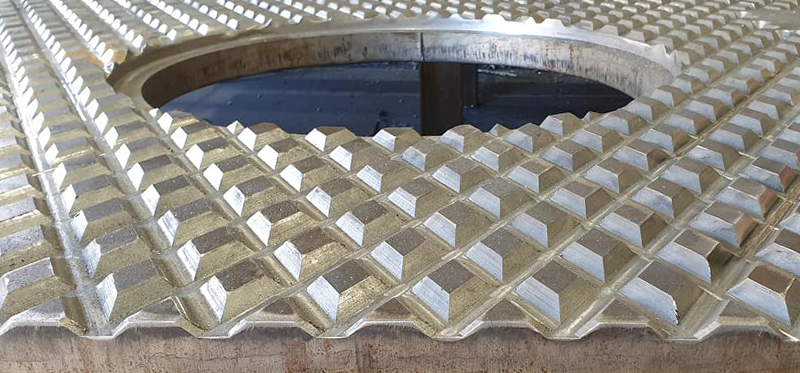

CNC machining

Our CNC machining employs the latest software, ensuring our three dimensional cutting and machining is of the highest precision for straight-line cutting and bevelling, countersinking and tapping holes.